December 14, 2022

Partnerships Propel College of Lake County Advanced Technology Center

The community college works with CDW to make its Advanced Technology Center a reality.

It all started with a strong strategic plan.

It was 2019, recalls Ali O’Brien, vice president of community and workforce partnerships at the College of Lake County in Grayslake, Ill. She and other leaders at CLC had just put the finishing touches on a document that defined the direction the community college would take over the next five years.

The plan hit on everything — student success, teaching and learning, the college’s commitment to equity and inclusion — but O’Brien had her focus on one strategy in particular: a call for building alliances with local industry.

“We had conducted a needs analysis across the county, and through that had identified four industry sectors where the number of new graduates we were producing wasn’t meeting local demand.” — Ali O’Brien

“We had conducted a needs analysis across the county, and through that had identified four industry sectors where the number of new graduates we were producing wasn’t meeting local demand,” she explains.

One of those industries was manufacturing. Located just north of Chicago, Lake County is home to the second-largest manufacturing workforce in Illinois, and the industry accounts for close to a third of the region’s gross domestic product.

“We realized that if we wanted these businesses to stay here and thrive, we’d need to open up that talent pipeline and supply them with a better-trained workforce,” she says.

At the time, CLC was running a welding program in conjunction with a local high school, which provided space for technical training. Participants in the program earned college credit as they pursued their high school diplomas, and they often completed their studies at CLC in preparation for jobs in the field.

“Our problem was, that welding lab was only accessible to adult students during nights and weekends,” O’Brien recalls. “And in addition to that, we were hearing from manufacturers that they needed people trained in industrial technology maintenance.”

By the Numbers

College of Lake County

9/25/69

Opened for business

225/804/582

Full-time faculty; part-time faculty; staff members

11,651

Students enrolled in the fall of 2022

182,000

Size of the CLC ATC in square feet

Manufacturing in Lake County

2nd largest

Manufacturing county in Illinois

98,900

Employees

$48.4B

Annual economic output

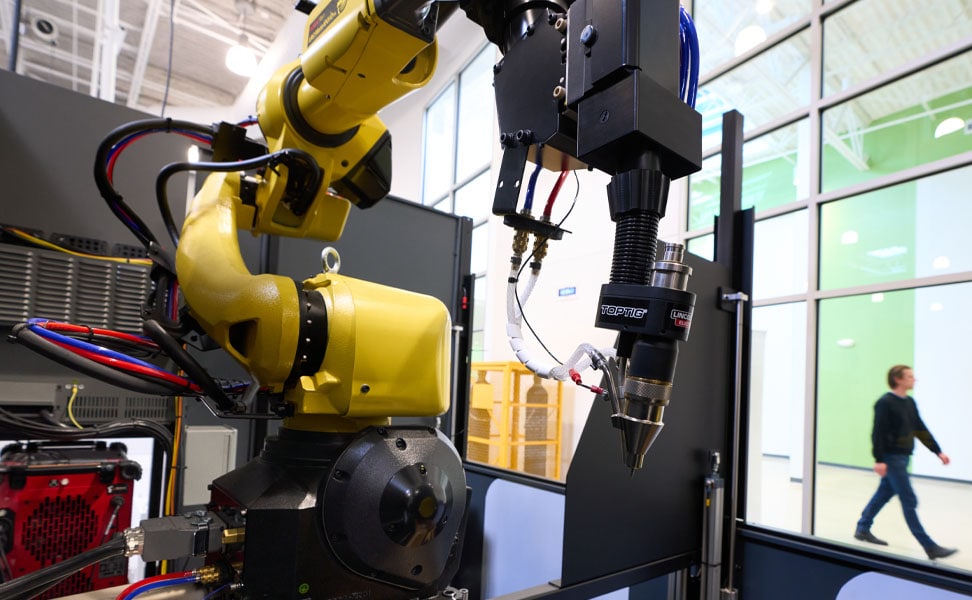

The word from local businesses was that Industry 4.0 — the “fourth industrial revolution” — had arrived. Manufacturing was rapidly evolving with the emergence of technologies like robotics and the Internet of Things, and even traditional disciplines like welding increasingly required highly advanced skills.

O’Brien and her team, looking to adapt, decided to meet with representatives from the National Coalition of Advanced Technology Centers. The organization helps colleges develop curricula and degree programs to entice students to pursue careers in Industry 4.0 fields.

“We determined it was important to move forward and invest in a new advanced technology center,” O’Brien says.

Like other ATCs around the country (the NCATC has helped establish nearly a dozen), the facility would be designed throughout with input from local stakeholders. Lake County manufacturers, K–12 schools, educators and students already enrolled at CLC — they would all be asked to participate in the project to ensure that it met the community’s needs.

A “Mutually Beneficial” Collaboration

Every advanced technology center is different from the next. There is no cookie-cutter formula for what technologies a college ATC should include, so success requires collaboration — leaning on experts to help get the job done.

As the College of Lake County launched its own ATC project, it looked to the NCATC and to local businesses big and small. And then, O’Brien says, it turned to CDW, a company she calls “a well-established partner.”

CDW, she explains, had worked with the college over the previous two years to provide it with educational technology and infrastructure support, “so our IT group had immediate access to CDW's resources and sales reps as we thought through the technology solutions we’d need at the center.”

The facility would be developed within a building that had previously housed a big-box store. To turn the space into a teaching and learning center intended to prepare students for careers in manufacturing, the ATC would need not only advanced technology fit for Industry 4.0 but also the basics, such as computer stations and networking.

“We knew we’d have robotic welding machines, for example, and that they could potentially be connected to the cloud,” O’Brien says. “So what were our requirements, infrastructurewise, to make sure something like that could actually happen?”

While the work associated with answering such questions would ultimately be up to a team of tech experts, it fell to CDW’s Julie Kriedemann to step in and lead the way.

A Chicago-based advanced technology account executive for higher education, Kriedemann remembers that she saw the project as a chance to further “a mutually beneficial partnership.” CDW “is really integrated into CLC’s business,” she explains. “Everything we do, we go above and beyond and try to provide value-added service.”

Working closely with the CLC team, including leaders from technology support, core systems and infrastructure, Kriedemann and her colleagues tackled everything from laptops and scanners to wireless access points and network switching.

“We kicked off in the middle of the pandemic, so that presented some challenges,” she recalls. To get around possible supply chain limitations and meet CLC’s deadlines, CDW’s main strategy “was to simply make sure we had sufficient lead times with our orders,” she adds.

CDW Executive Account Manager Eric Cheng, who also provided leadership during the project, notes that most of the technology CLC implemented was no different from what they might deploy anywhere else.

“What made it unique is how it’s being used,” he says, noting that the completed ATC was ready in time for the fall 2022 semester. “Here, it’s all about hands-on experience in a setting just like they’re going to see when they work in industry.”

Technology Checklist

The College of Lake County ATC includes the latest in manufacturing technology, from robotic welders and pipe-bending equipment to laser and plasma metal-cutting machines. It also includes traditional tools for techniques like oxy-acetylene torch welding, and it features stations devoted to teaching students the basics of mechanical and electrical systems.

Still, says CLC Vice President Ali O'Brien, none of the equipment within the ATC would be usable without the educational technology the college has put in place to support it. Among the tech that CDW brought to CLC to make learning in this unique environment easier:

- • Cisco wireless access points, network switches and IP phones

- • Eaton and APC power devices

- • Raritan kernel-based virtual machine switches

- • HP monitors, laptops, desktops and docking stations

- • HPE servers

- • Tripp Lite charging carts

- • Poly videoconferencing kits

A Space for Innovation

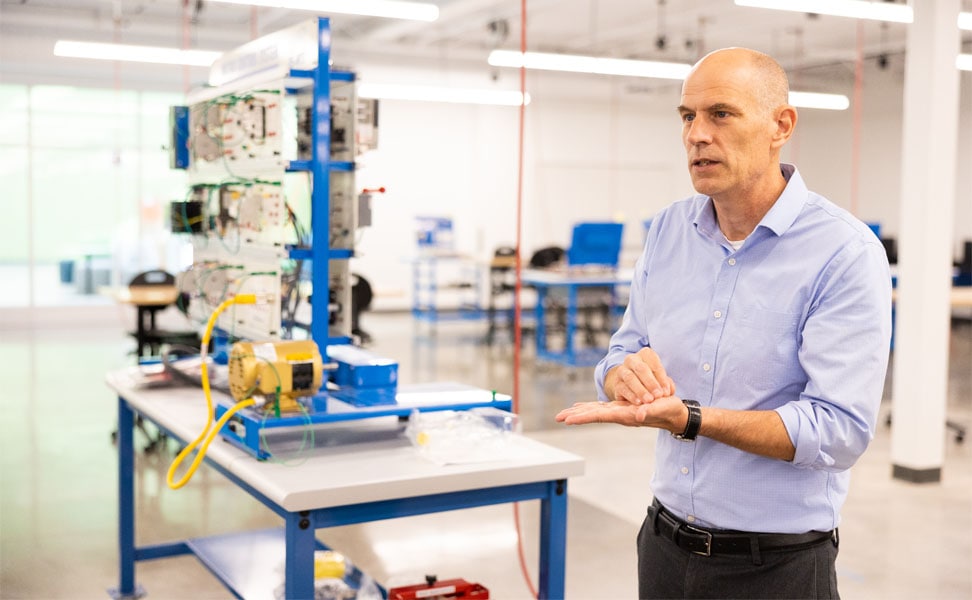

One person who couldn’t agree more with Cheng more: ATC Director Jon Hardbarger.

“Innovative education has to create an environment that engages students,” says Hardbarger, who was hired by the college early in 2021, soon after construction on the facility began.

The ATC was envisioned as a space where innovation would be the norm — where students would feel free to be innovative themselves while working with cutting-edge technologies.

“We want them to come in here and troubleshoot and make mistakes and develop critical thinking skills. They need to be able to see the relevance of what they’re learning and immediately apply it to the real world.” — Jon Hardbarger

“We want them to come in here and troubleshoot and make mistakes and develop critical thinking skills,” he explains. “They need to be able to see the relevance of what they’re learning and immediately apply it to the real world.”

In keeping with local manufacturers’ recommendations, the facility currently includes two primary educational programs. In one part of the building, students learn skills in welding and fabrication technology, while another area is devoted to industrial technology and the repair and maintenance of manufacturing equipment and systems.

CDW helped design what Hardbarger describes as “teaching nooks” throughout the ATC: ed tech-equipped stations instructors use to supplement students’ practical learning with short classes and presentations.

“If they want to show a PowerPoint or a video, everything they need is there,” he explains. Teachers also have access to cameras and large mobile displays that can be wheeled into position as desired. “Maybe there’s a student in a welding booth, and the teacher wants people to look at their technique. You can’t put them in there while they’re welding, so instead you have them watch on the screen.”

Both Hardbarger and O’Brien say the CDW team has remained in close contact since the ATC opened and will play an important role in its evolution.

“It’s been a really fruitful partnership,” O’Brien notes. “They’ve gone from just being another vendor who would bid on our RFPs to where now they’re attending our quarterly meetings with senior leaders and helping us think through how we can better serve the region.”

The college’s ATC wouldn’t have happened without support from industry or consultation from the NCATC, or the countless meetings that were held with community stakeholders such as the college’s own instructors and representatives from local schools.

“And it wouldn’t have happened without CDW,” O’Brien says. “They’ve been here to support us the entire way.”

Story by Chris Hayhurst, a freelance writer who covers education technology and healthcare, among other topics. He's a regular contributor to the CDW family of technology magazines.

Photography by Matthew Gilson; Hilary Domke/College of Lake County (Jon Hardbarger)

Learn more about what CDW can do for higher education institutions.

MKT54027